It's been lying on the shelf for a while and I have always kept the project on hold because of the challenging changes I had in mind and now ,I think I am read for this build.

As soon as I opened the box I decided there and then , that the wooden part of the deck has to be made of real wood. You can buy these ready made, but they are so damm expensive and I have already spent a fortune on photoetch and other miscellaneous fittings, but above all I wanted to make the wooden part of the deck scratchbuilt. It's more of a challenge.

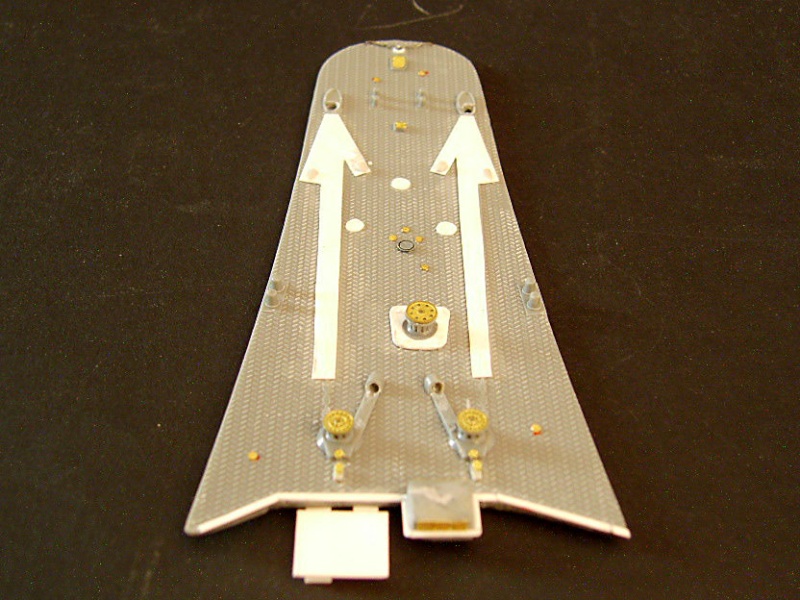

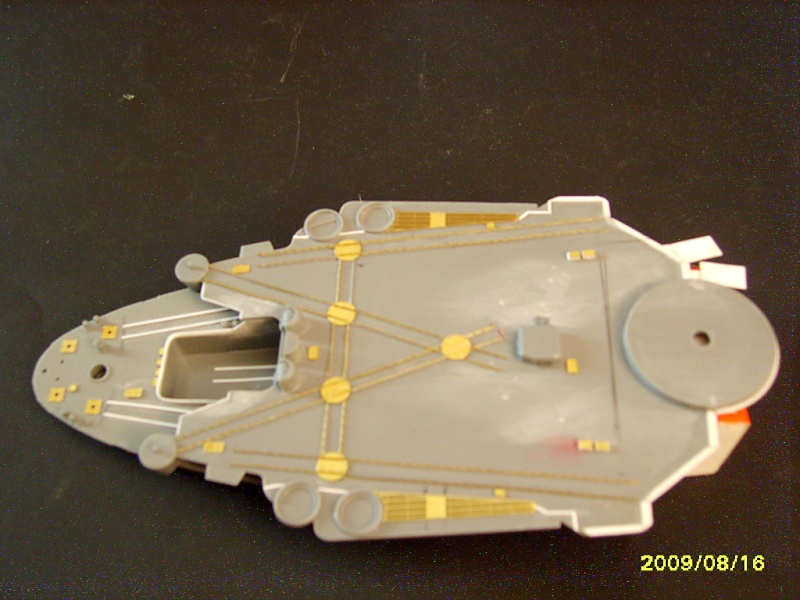

It took quite a while to measure and shape an exact fit of this new deck with the other two parts which obviously had to be sawn off from the provided parts of the kit, which were now totally destroyed anmd then discarded. The whole wooden deck was made out of plastic card and strengthened with thick plastic evergreen strips from underneath. When I had a perfect fit, after about six attempts, I covered the prepared plastic card deck with a very thin wood laminate to simulate the real thing. When dry the whole deck was trimmed and sanded vigourously then lined with a very thin tip pencil to simulate the planing on the deck. A jig was made with a simple steel rule to keep the spacing even and accurate. The planking is very fine and can barely be seen in the picture provided. I t was a tedious job and demanded a lot of patience. The deck was given ample coats of a satin finish varnish as it is in its present state which is not so attractive. A few white stains have also to be corrected . With all corrections affected it will be sanded down and given a coat of matt varnish, which will make it look totally different to its present state.

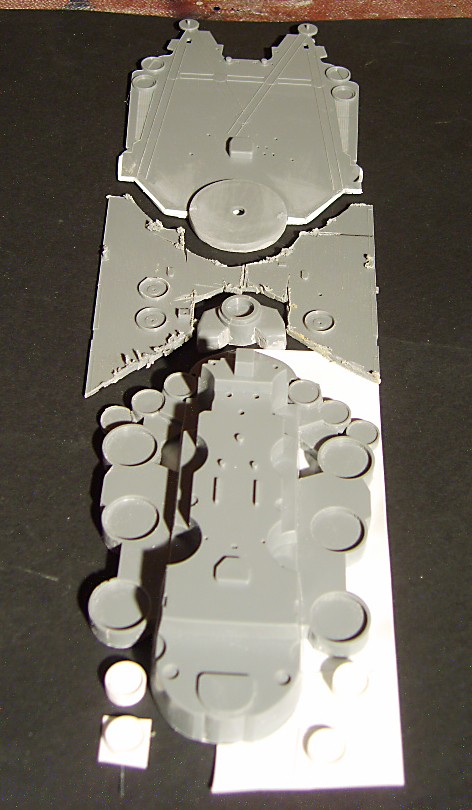

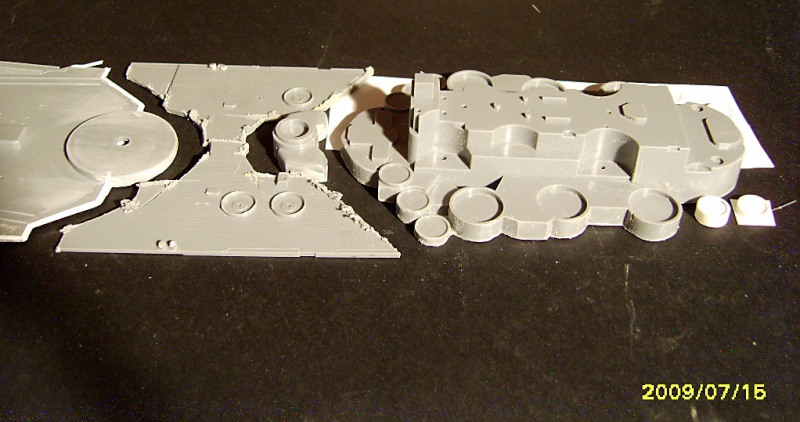

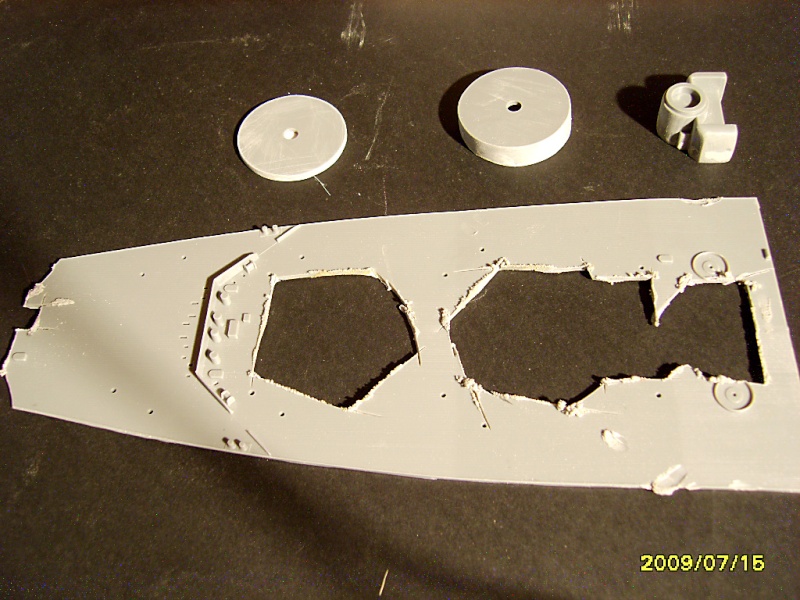

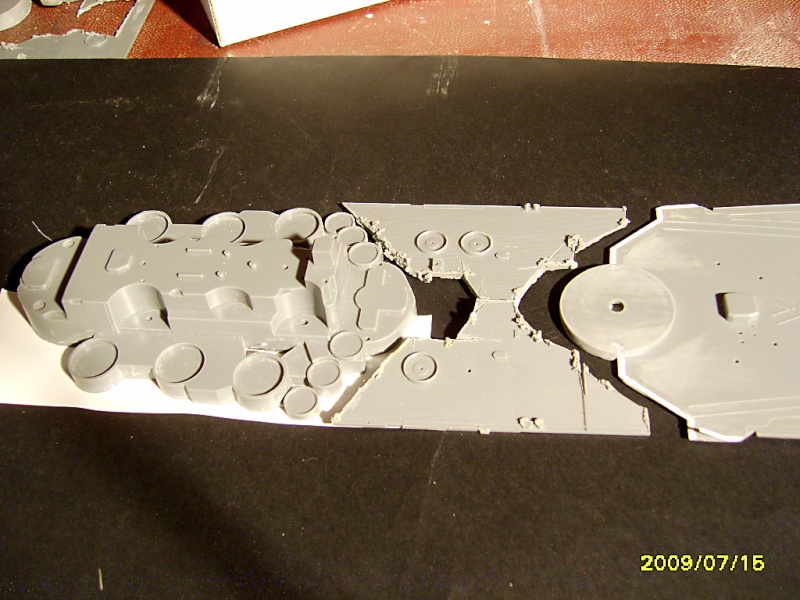

Now for the tricky bit , I had to cut and prise out the parts of the superstructure from the moulded part of the supposed to be wooden deck provided by the kit. This wasn't easy and have various cuts in my fingers to prove it. Various tools were used. Care had also to be taken to take away the thickness of the plastic to end up with correct levels all round. Some damage was done in the process and loads of filler had to be used to correct the said damage. Several gun column platforms were destroyed in the processed and new ones had to be scratchbuilt. Of course all the small fittings , raised detail and gun positions on the discarded decks have to be scratchbuilt and many resin copies have to be made with the help of Alex of course

Next step is to work on the bow and stern of the ship and later I will start works on the hull, which will definetely keep me very occupied.

I hope I didn't bore you to bits but I think , step by step build articles will further enhance the already most popular club forum.

Louis